(Third in a series about shady solar workmanship, how to tell the difference between a good and bad solar installation, and how to protect yourself from unethical or incompetent installers. Thanks to Jonathan Williams, my partner and VP of Installation & Service, for contributing stories “from the trenches” for this series.)

So we’re midway through this blog series about how sub-optimal installation affects more than the aesthetics of your solar energy system – it affects the safety, reliability and overall performance, too. Today, I’ll talk about mounting solar panels on the racking system (the rails) that support the panels, and mounting the racking on the roof. Mounting should be a simple affair, but small mistakes — like the 6 shown below — can lead to a mountain of misery.

First example: The photo above shows a solar panel attached to a rail with a mounting clip (in the red circle). The rail is not long enough, so the installer bent the mounting clip to make it fit — the left edge of the clip should be straight up and down. Considering that manufacturers typically require at least ¼” of rail extending beyond the outside edge of the clip, for stability, this is just plain wrong.

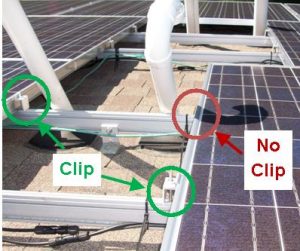

How not to mount solar panels, exhibit B: Each panel must be secured to the rail at four points. In the picture below, you can see the installer forgot to install a clamp or ran out. Either way, that’s unacceptable. Maybe one clamp doesn’t seem like a big deal, but you want your system to last at least 50 years. Any weakness in the system may shorten its life. Besides, if the installers missed this, what else did they miss?

Solar panels must have a gap between rows. Why? Because the frames and glass of the panels need room to expand and contract with the weather. (Yes, glass and metal, like wood, are affected by temperature.) This is such an important aspect of installation that panel manufacturers will void the warranty on a system with no gap between panels. We think the panels in the picture below were installed without a gap, although it’s also possible that the clamps were loose and the panels shifted after the installation.

The rail for solar systems must be properly supported and grounded. Two pieces of rail require a “rail splice” for stability and safety. The photo on the left shows two rails not spliced together, which creates a weak spot in the system supporting the panels. Also, rail manufacturers specify how far apart rail supports should be from each other and from each end of the rail. A typical recommendation calls for 12-16” between the end of the rail and the first support. Yet the photo to the right shows more than 50” between the end of the rail and the first support! When Jonathan went on this roof, he literally could bounce the panels against the roof because of the amount of cantilever created by the installer’s shoddy work.

Mounting anything to your roof introduces the possibility of leaks. Proper flashing is the best way to prevent that. This photo shows an “L-foot” bracket mounted to the roof with a blob of silicone instead of proper flashing. And, the bracket isn’t even bolted to the rail! This will allow the rail to move and flex more than it is rated for, putting more load on other components of the mounting system.

Is this a lot of worry about nothing? Consider the old song, “Dem Bones”. The foot bone’s connected to the ankle bone. The ankle bone’s connected to the leg bone…The entire structure attaching your solar energy system to your roof should be safe and attractive, from panel clamp and rail to L-foot and flashing. Any mistakes or oversights in the structure mean the whole system is less durable and sturdy, and may perform at less than its potential. When you’re investing in solar, you want the whole system to be installed with care and professionalism.

Next week: The Thrilling Conclusion

Did you miss the earlier installments? Click here for Part 1.