I’ve been having an entertaining back-and-forth with the good people at the Massachusetts Solar Owners Association (MASOA) on their blog, about the current state of the market for energy-efficient trucks and vans.

New England Clean Energy’s “fleet” includes 3 used hybrid Priuses for the sales team and 3 used, gasoline-fueled utility vans for our installation crews. The Priuses all have around 200,000 miles on them and are going strong. The vans carry ladders, coils of electrical wire, racking, inverters, and of course piles of solar panels to job sites. My partner Bill Carr, on a mission to make our fleet more environmentally friendly, once insisted we test packing a job’s worth of equipment into a Prius instead of a van. It worked for the 6-panel installation, but that was about it.

Much as we’d like an all-green fleet, electric and hybrid trucks are just not ready for prime time yet. The Toyota RAV4 mentioned by MASOA is a passenger car with a mini-SUV body on it, i.e. not roomy enough for all our tools and equipment. Progress is being made with hybrid vans, but the car industry seems focused on passenger vans, not commercial ones.

We’ve looked into converting our vans to bio diesel. Even if you get the oil for free, the staff time and expense of collecting, filtering and preparing the fuel makes it cost-prohibitive.

Sadly, we have a long way to go before auto companies make real electric trucks. I guess it comes down to this: a normal 35 MPG car typically gets 100 miles from a charge of its electric counter-part’s battery. A similarly outfitted 10 MPG truck would get 33 miles on a charge, or would need 3x the amount of batteries to get 100 miles. However, 3x the amount of batteries would require 3x the charging time (12 hours), or a special over-sized charging station to charge the bigger batteries in the 4-hour time frame. Charging stations are rare enough; over-sized stations are very unlikely to be available any time soon

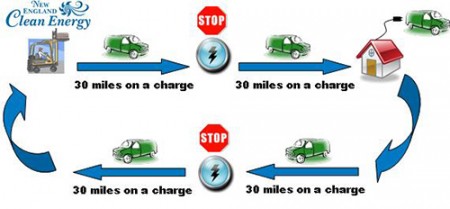

If we went with the one battery going 33 miles on a charge and then needing to be charged, our vehicles would need to stop three times for a minimum of four hours each just to make it out and back to one of our installation jobs, which are all within one hour or 60 miles of our office. Clearly, that’s not realistic:

It bugs us to no end to drive up to a customer’s home to install emissions-free technology in a CO2 emitting van. Someday, new battery technology will provide better energy density and a rapid recharge rate, and car companies will make energy-efficient work vehicles. In the meantime, we’ll minimize our carbon footprint.by keeping our service area relatively small, and our pre-job checks tight to prevent second trips back to the warehouse.

If you liked this article, you might also enjoy:

Think Globally, Buy Locally